Understanding Quality Management Team Roles & Responsibilities

Quality isn't just an inspection step; it's a business strategy.

A recent ASQ study estimates that the cost of poor quality can reach 15–20% of a company's annual revenue. From recalls in automotive giants to...

Understanding the Key Concepts of Control Charts

Also known as the Shewhart chart, control charts are used for statistical monitoring of operations in an organization. The details plotted are in order of time. A regulation map still includes the typical center...

Understanding Six Sigma in Software Development

Six Sigma, a methodology traditionally associated with manufacturing, has found a valuable place in software development processes. By reducing defects and variability, Six Sigma enhances the quality and performance of software products.

The blog will...

The Role of Six Sigma in Finance Cost Reduction

In today's competitive business environment, organizations in the finance industry are constantly looking for ways to reduce costs and increase efficiency. Six Sigma, a data-driven methodology for improving process quality and reducing defects, has...

Boosting Employee Engagement with Six Sigma

Employee engagement is a critical factor in the success of any organization. Engaged employees are more productive, innovative, and motivated, which leads to better business results. However, many organizations need help to maintain high...

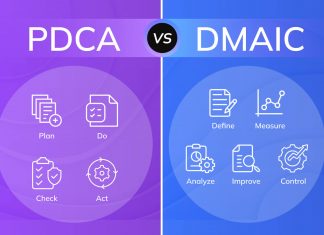

PDCA vs DMAIC: How to Choose the Right Improvement Method in 2026

Continuous improvement isn’t optional anymore; it’s the only way to keep processes stable, costs under control, and customers satisfied. Whether you’re trying to reduce defects on a production line, stabilize a service desk, or...

10 Steps on How to Implement a Quality Management System Successfully

The implementation of a quality management system is both a science and an art. It uses information, but also requires the ability to get people involved. It takes an analytical approach, but innovation is also...

What Is Kaizen Methodology: 6 Key Benefits

Since the end of the Second World War, Kaizen has been adopted by both massive multinational and small firms in Japan. Productive work and efficiency require a clean atmosphere, protection, and discipline. So, Kaizen's...

What is FMEA? An Overview of Failure Mode Analysis

Problems and defects are costly. None of the businesses are willing to shell out excessive money from their pocket. But there are numerous high-profile examples of product recalls due to poorly designed products /processes....

Understanding the Plan Do Check Act (PDCA) Cycle

Most businesses want to get better, but turning that desire into actual improvements can be hard. Things like too many rules, separate working groups, and a fixed way of doing things can get in...