Six Sigma, a methodology traditionally associated with manufacturing, has found a valuable place in software development processes. By reducing defects and variability, Six Sigma enhances the quality and performance of software products.

The blog will cover the Six Sigma methodologies, the benefits of implementing Six Sigma in software development, the tools used in Six Sigma, and the steps required to implement Six Sigma in software development. It will also provide case studies of companies that successfully implemented Six Sigma in their software development process.

Table of Contents:

- What is Six Sigma?

- What is Six Sigma in Software Development?

- The Six Sigma Methodology

- Benefits of Using Six Sigma in Software Development

- Six Sigma Tools

- Implementing Six Sigma in Software Development Process

- Real World Case Study of Using Six Sigma in Software Development

- Conclusion

What is Six Sigma?

Six Sigma is a quality management methodology aiming to improve product and service quality by identifying and eliminating defects. It is a data-driven approach that uses statistical methods and tools to measure and analyze processes’ performance and identify improvement areas.

Six Sigma is based on five core principles: Define, Measure, Analyze, Improve, and Control (DMAIC), and it has been widely adopted in various industries, including manufacturing, healthcare, finance, and software development. Its goal is to reduce variation and achieve near-perfect performance, with a target of no more than 3.4 defects per million opportunities.

What is Six Sigma in Software Development?

Six Sigma in software engineering is the application of the Six Sigma methodology to the software development process. Six Sigma is a data-driven approach that uses statistical methods to identify and eliminate defects and reduce variation in a process.

By applying Six Sigma to software development, teams can use data to identify and eliminate defects in the software, reduce variation in the development process, and improve the overall efficiency and effectiveness of the process.

The goal of Six Sigma in software development is to deliver high-quality software that meets or exceeds customer expectations while reducing costs and improving efficiency.

The Six Sigma Methodology

In software development, Six Sigma improves the development process, reduces defects in the code, and improves the overall quality of the software.

Following are the most commonly used Six Sigma methodologies.

DMAIC

One of the most commonly used Six Sigma methodologies in software development is DMAIC (Define, Measure, Analyze, Improve, Control). The DMAIC process can be used to identify and eliminate the root cause of bugs in the code, reduce the time it takes to complete a project and increase the efficiency of the development process.

For example, a software development team could use DMAIC to identify and eliminate the root cause of a bug in their code that was causing the software to crash. By identifying the root cause of the problem, the team can implement a solution that will prevent the bug from occurring in the future.

This can help the team to increase the efficiency of the development process, reduce the time it takes to complete the project and improve the overall quality of the software.

DMADV

The DMADV (Define, Measure, Analyze, Design, Verify) methodology is used when creating a new process or product. It involves defining customer needs, measuring key performance indicators, analyzing data to identify root causes of defects, designing a new process, and verifying that the process meets customer needs and requirements.

For example, A software development team uses DMADV to design and implement a new testing process for their software. They define customer needs, measure key performance indicators, analyze data to identify root causes of defects, design a new testing process, and verify that the process meets customer needs and requirements.

Lean Six Sigma

Lean Six Sigma methodology combines the principles of Lean and Six Sigma to help software development teams improve their processes and deliver high-quality software more efficiently. The Lean methodology focuses on eliminating waste and inefficiencies, while Six Sigma focuses on reducing defects and variation in the process.

For example, a software development team uses Lean Six Sigma to improve their software development process. They identify and eliminate waste and inefficiencies and use Six Sigma tools to reduce defects and variation in the process. This leads to increased efficiency and improved software quality.

Design For Six Sigma (DFSS)

Another Six Sigma methodology used in software development is Design for Six Sigma (DFSS). DFSS can be used in the design phase of software development to ensure that the design meets customer requirements and reduces the risk of defects.

By using DFSS, the software development team can ensure that the design of the software is optimized for quality, performance, and customer needs.

For example, a software development team could use DFSS to design a new software application that meets the specific needs of its customers. By using DFSS, the team can ensure that the design of the software is optimized for quality, performance, and customer needs, which can help to reduce the risk of defects and improve the overall quality of the software.

Benefits of Using Six Sigma in Software Development

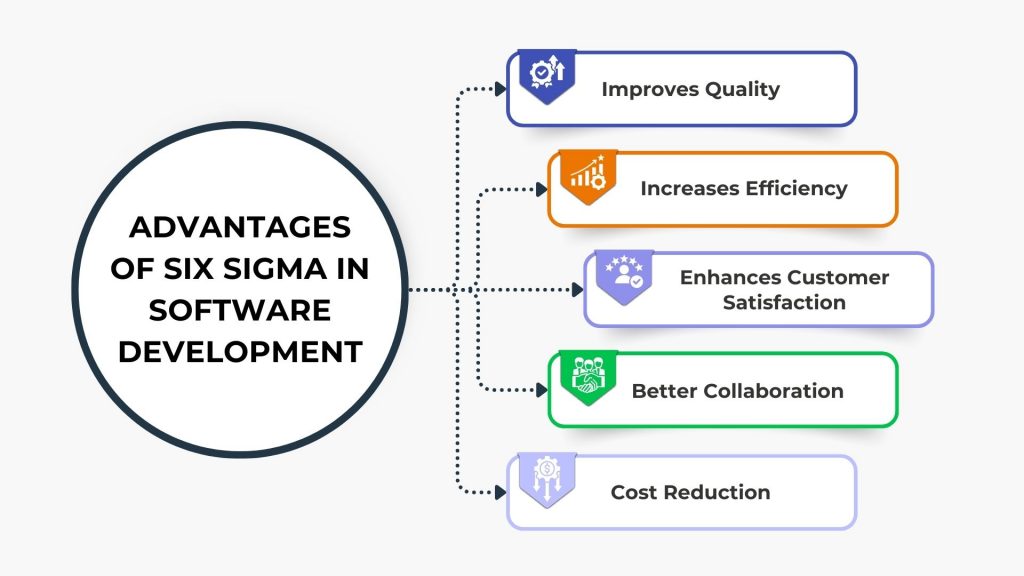

Six Sigma is a quality management methodology that aims to reduce defects and improve efficiency in a process. In the context of software engineering, Six Sigma can provide several benefits, including:

- Improves Quality: By using Six Sigma tools and techniques, such as statistical process control and design of experiments, software development teams can identify and eliminate sources of defects in their processes

- Increases Efficiency: Six Sigma also emphasizes process improvement and streamlining, which can help teams to complete projects faster and with fewer resources

- Enhances Customer Satisfaction: By reducing defects and improving efficiency, Six Sigma can help software development teams to deliver higher-quality products that better meet the needs of their customers

- Better Collaboration: Six Sigma emphasizes the importance of cross-functional teams and clear communication, which can foster better collaboration between different departments and stakeholders

- Cost Reduction: Six Sigma can help teams to reduce the costs associated with defects and rework by identifying and eliminating sources of waste in their processes

Six Sigma can help software development teams to deliver higher-quality products more efficiently, with greater customer satisfaction and cost reduction.

Six Sigma Tools

Six Sigma tools can be used to identify and eliminate sources of variability and defects in the software development process. Some common Six Sigma tools used in the process include:

Statistical Process Control (SPC)

SPC is a tool for monitoring and controlling a process using statistical techniques to identify patterns and trends in the data. This can be used to identify patterns in the software development process, such as defects or delays, and take action to correct them.

Failure Modes and Effects Analysis (FMEA)

FMEA is a tool for identifying potential failure modes in a process and assessing the potential impact of those failures. This can be used to identify potential risks in the software development process and take steps to mitigate them.

Design of Experiments (DOE)

The design of experiments is a tool for understanding the relationship between inputs and outputs in a process. This can be used to understand how different factors, such as design choices or testing methods, affect the quality of the software.

Flowcharting

Flowcharting is a tool for visually representing the steps in a process. This can be used to identify bottlenecks and inefficiencies in the software engineering process and take steps to improve them.

Overall, Six Sigma tools can improve the quality of the software development process by identifying and eliminating sources of variability and defects. This can lead to faster development times, fewer defects, and higher customer satisfaction.

Implementing Six Sigma in Software Development Process

Implementing Six Sigma in software engineering involves a structured approach to identifying and eliminating defects during software development to improve overall quality and efficiency. The Six Sigma methodology is made up of five key phases, each of which is designed to help organizations improve their processes and increase efficiency.

Define

The first step in implementing Six Sigma in software development is defining the problem or improvement opportunity. This involves identifying the specific areas of the development process that need improvement and determining the project’s goals and objectives. This could include identifying specific customer complaints, high rates of defects in the software, or long lead times for the process. By clearly defining the problem or opportunity, the project team can focus on specific areas that need improvement.

Measure

The next step is to measure the current performance of the software development process. This involves collecting and analyzing data to determine the current defects and other quality issues. This data can be collected through customer complaints, bug reports, testing results, and other metrics relevant to the process. By measuring the current performance, the project team can establish a baseline for the process and determine the scope of the problem.

Analyze

Once the data has been collected and analyzed, the next step is to analyze it to determine the root cause of the problems. This involves using statistical tools and techniques such as the Fishbone diagram, Pareto Chart, and Root Cause Analysis to identify patterns and trends in the data and the underlying causes of the defects and other quality issues. This step is crucial in understanding why the problems are occurring and what needs to be done to address them.

Improve

This step involves implementing solutions to address the root causes of the problems identified in the previous step. These solutions may include changes to processes, tools, or training programs. This step aims to eliminate the sources of defects and improve the quality of the software.

Control

The next step is to control the entire development process to ensure sustained improvements are made in the previous step. This involves monitoring the process and making necessary adjustments to ensure that the quality of the software remains high. This can be done by implementing process control mechanisms such as Statistical Process Control (SPC) to ensure that the process remains within acceptable limits.

Optimize

Continual optimization of the process is done by reviewing and analyzing the data again to ensure that the process is continuously improved and problems are minimized. This step ensures that the process is continuously improved and that the software development process remains efficient and effective.

This could include regularly reviewing process metrics and customer feedback and making adjustments to the process as necessary to improve efficiency and quality.

Real World Case Study of Using Six Sigma in Software Development

Implementing Six Sigma in software development can be challenging, but by following the methodology and using the right tools and techniques, organizations can achieve significant improvements in quality and efficiency. It is important to have a clear vision and strategy and adequate resources and support from leadership to implement Six Sigma in software engineering effectively.

One example of a company successfully implementing Six Sigma in its software development process is GE Software. GE Software, a subsidiary of General Electric, specializes in developing software for industrial automation and control systems. However, they faced a major challenge with many defects in their software products, which led to customer dissatisfaction.

To address this problem, GE Software implemented Six Sigma in its software development process. They began by defining the problem and setting goals for the project, which included reducing the number of defects in their software by 50% and improving overall customer satisfaction.

Next, they measured the current performance of the software development process by collecting data on the number of defects, customer complaints, and other relevant metrics. This data was then analyzed to determine the root causes of the defects. By using statistical tools and techniques, they were able to identify patterns and trends in the data and pinpoint the underlying causes of the defects.

With the root causes identified, GE Software implemented solutions to address the issues. For example, they made changes to their processes, tools, and training programs to eliminate the sources of defects and improve the quality of the software. They also implemented process control mechanisms such as Statistical Process Control (SPC) to ensure that the process remained within acceptable limits.

Finally, they continually optimized the process by regularly reviewing process metrics and customer feedback and making adjustments to the process as necessary to improve efficiency and quality.

As a result of this effort, GE Software successfully reduced the number of defects in their software by 50% and improved overall customer satisfaction. This not only helped them retain existing customers but also helped them gain new customers.

In addition, the successful implementation of Six Sigma in their software development process also helped them improve efficiency and reduce costs.

Conclusion

Six Sigma is a powerful methodology that can be used to improve the quality and efficiency of the software development process. By using Six Sigma tools such as DMAIC, SPC, FMEA, DOE, and flowcharting, organizations can identify and eliminate sources of variability and defects, leading to faster development times, fewer defects, and increased customer satisfaction.

Implementing Six Sigma in software development can help organizations to achieve their goals of delivering high-quality software on time and within budget.

If you’re planning to give a boost to your career in quality management, certification is mandatory. A Six Sigma certification is globally accepted, enabling you to get global opportunities.

We at Invensis Learning offer many quality management certifications, which include:

- Lean Six Sigma Yellow Belt Certification

- Lean Six Sigma Green Belt Certification

- Lean Six Sigma Black Belt Certification

Glossary

- DMAIC: A Six Sigma methodology used to improve an existing process. It stands for Define, Measure, Analyze, Improve, and Control

- Software Development: Designing, building, testing, and maintaining software applications

- Process Improvement: Identifying and eliminating inefficiencies to increase efficiency and reduce costs

- Statistical Process Control (SPC): A method used to monitor and control a process using statistical tools and techniques

- Failure Modes and Effects Analysis (FMEA): A methodology to identify potential failure modes and their effects on a process

- Design of Experiments (DOE): A statistical method used to design and analyze experiments to identify the factors that affect a process

- Continuous Improvement: The ongoing effort to improve processes and increase efficiency