Quality Control (QC) is a crucial process for any business aiming to deliver exceptional products or services. By ensuring that outputs meet defined quality standards, QC helps companies maintain consistency, enhance customer satisfaction, and reduce resource wastage. Whether it’s a product on a store shelf or a service offered to clients, Quality Control is the backbone of reliability and excellence.

Simply put, the definition of Quality Control is the process of testing and verifying whether a product or service meets established quality benchmarks. The meaning of Quality Control applies across industries, from manufacturing to healthcare, ensuring safety, compliance, and trust.

Beyond customer satisfaction, QC directly impacts a company’s efficiency and profitability. By identifying defects early, it minimizes errors and reduces the cost of rework or recalls. This not only improves the product’s reliability but also strengthens the brand’s reputation in competitive markets. Industries like manufacturing, healthcare, and pharmaceuticals often rely heavily on QC to meet regulatory requirements and maintain safety standards.

In this blog, we’ll take an in-depth look at the role of Quality Control, its definition, importance, and different QC methods. Whether you’re a business owner, a professional aiming to improve processes, or someone exploring career opportunities in Quality Control, this guide will provide valuable insights to help you understand its significance and applications.

Table of Contents:

- What is Quality Control (QC)? Definition

- Major Components of Quality Control

- Types of Quality Control Methods

- Benefits of Quality Control

- Quality Control Vs. Quality Assurance

- Example of Quality Control in Industries

- Careers in Quality Control

- Conclusion

- FAQs on Quality Control (QC)

What is Quality Control (QC)? Definition

Quality Control (QC) definition: It is the process of testing, inspecting, and verifying whether a product or service meets established quality standards. In simple terms, the meaning of Quality Control is making sure that every output, whether physical goods or services, matches what customers expect and what regulations demand.

The concept of quality may differ across industries, but in QC, it always comes down to meeting standards, ensuring consistency, and delivering value. Businesses use QC to assess, maintain, and continuously improve their products or services, thereby protecting customer trust and satisfaction.

The primary goal of Quality Control is twofold:

- To ensure that products and services are consistent and reliable, so customers receive the same high standard every time.

- To minimize defects and errors by monitoring outputs during production or delivery.

QC isn’t just about identifying mistakes after they occur; it’s about building systems that prevent defects, reduce rework costs, and maintain brand credibility.

Major Components of Quality Control

Quality Control (QC) is integral to maintaining high standards in product and service delivery. It encompasses a variety of components, each playing a crucial role in ensuring that the final output meets or exceeds the expected quality.

The components include:

- Inspection: This involves regularly examining products, materials, or services to identify any defects, non-compliance, or deviations from the established quality standards

- Testing: Various tests assess performance, functionality, or other characteristics, ensuring products or services meet quality expectations

- Statistical Process Control (SPC): This employs statistical methods to monitor and control production processes, keeping them within acceptable quality limits

- Documentation and Records: Keeping detailed and accurate records of inspections, tests, and corrective actions is essential for maintaining traceability and accountability

- Corrective Action: Whenever quality issues are identified, appropriate measures are taken to rectify them and prevent their recurrence

- Training and Education: Empowering employees with the necessary skills and knowledge is vital for effectively maintaining quality standards

- Continuous Improvement involves analyzing data and feedback to refine and enhance the quality management system

In many organizations, these tasks are overseen by a Quality Control department, which acts as the central function ensuring consistency across all operations. Depending on the industry, the QC department may include inspectors, engineers, or specialized technicians dedicated to safeguarding product or service quality.

Quality Control Process

Quality testing is integral to every stage in a manufacturing or business workflow. It often begins with employees sampling materials from production lines, finished goods, and raw inputs. Testing during various production phases helps identify issues early, pinpoint their root causes, and implement corrective actions to prevent recurrence. This approach minimizes defects and ensures a streamlined process.

In non-manufacturing settings, quality testing can take the form of customer feedback through reviews, surveys, questionnaires, and internal checks like inspections and audits. Businesses adopt these measures to confirm that their products or services meet safety standards, comply with regulations, and satisfy consumer expectations.

QC Across Industries

Quality Control (QC) is vital across all sectors, ensuring consistency and reliability in products and services. In manufacturing, QC involves inspecting raw materials, semi-finished items, and final products to ensure they meet set standards. This reduces defects and maintains consistency in output. In the food industry, QC safeguards consumers by checking for contaminants and ensuring compliance with health and safety regulations.

In pharmaceuticals, QC verifies the potency, purity, and safety of medicines, ensuring they meet stringent regulatory standards. Similarly, in the software industry, QC encompasses extensive testing to identify bugs and ensure applications perform. Regardless of the industry, QC remains a cornerstone for achieving high-quality outcomes, improving customer satisfaction, and building a trustworthy brand reputation.

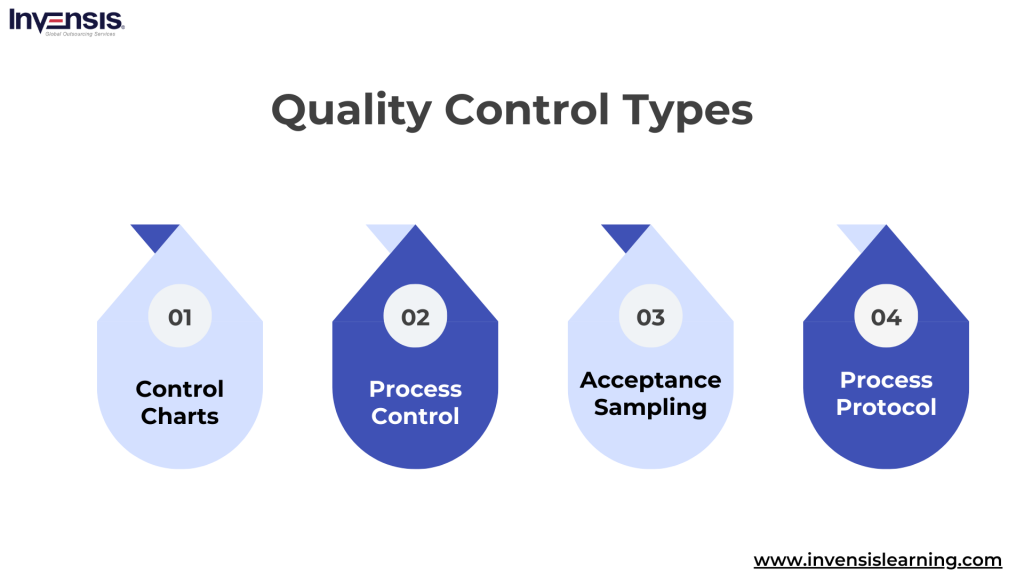

Types of Quality Control Methods

Quality Control (QC) is a diverse and dynamic field, with its methods varying significantly across different industries. The type of QC employed often depends on the specific requirements and risks associated with a particular sector.

For instance, industries like food and pharmaceuticals, where consumer safety is paramount, might lean towards more scientific and rigorous QC methods.

In contrast, fields like education or coaching might adopt a more qualitative approach, focusing on holistic improvement. Regardless of the industry, QC is fundamentally about meticulous attention to detail and robust research methodology.

Several key types of Quality Control methods are commonly used across various industries:

Control Charts

Control charts are graphical representations that track process changes over time. By statistical analysis, businesses can determine whether their manufacturing or service processes are within the control limits.

Process Control

This involves continuous monitoring and adjusting processes to ensure consistent quality and improved performance. It often includes technical methods like feedback loops and industrial controls, especially in manufacturing.

Acceptance Sampling

This method uses statistical sampling to decide whether a batch of products meets the overall manufacturing standards, helping make informed decisions about product quality.

Process Protocol

This approach maps out the design and implementation processes, setting evaluative indicators for each step to ensure that each production or service delivery phase meets quality standards.

In practice, businesses often combine these types of QC methods depending on the complexity of their processes. For instance, a pharmaceutical company may lean on rigorous testing and documentation, while a food manufacturer may emphasize acceptance sampling and compliance checks.

Benefits of Quality Control

Quality Control (QC) is more than just a set of procedures; it’s a pivotal aspect of business operations that brings numerous benefits to the company and its customers. By enforcing QC measures, organizations can enhance their product and service quality and gain a competitive edge in the market.

Key benefits of Quality Control include:

- Customer Satisfaction: QC ensures products and services consistently meet or exceed customer expectations, fostering higher satisfaction and loyalty. This leads to repeat business and positive word-of-mouth referrals.

- Defect Prevention: Early identification and correction of issues in the QC process prevent defects, reducing costly recalls or rework. This also enhances the overall reliability of the product or service.

- Cost Reduction: Implementing QC measures leads to reduced waste, lower production costs, and improved efficiency, contributing to significant cost savings. This financial efficiency can be reinvested into further improvements or innovation.

- Compliance and Regulations: Adherence to industry standards and regulatory requirements through QC helps avoid legal issues and penalties, ensuring smooth business operations and maintaining corporate integrity.

- Brand Reputation: High-quality outputs build a positive brand image, enhancing reputation and market competitiveness. A strong reputation is invaluable for long-term business growth and success.

- Increased Efficiency: QC optimizes processes, leading to higher productivity and streamlined operations, faster delivery times, and increased capacity.

- Risk Mitigation: Through rigorous testing and inspections, QC helps identify potential risks and hazards, allowing businesses to address them proactively and maintain a safe environment for employees and customers.

- Continuous Improvement: A focus on QC encourages ongoing enhancement of products, services, and processes, fostering a culture of innovation and adaptability within the organization

- International Competitiveness: High-quality products enabled by QC can facilitate entry into global markets, increasing a company’s competitiveness on an international scale and opening up new revenue streams

- Customer Retention and Loyalty: Satisfied customers, as a result of high-quality products or services, are more likely to stay loyal and recommend the brand, contributing to the long-term success and sustainability of the business

In essence, the benefits of Quality Control combine short-term efficiency with long-term business resilience, helping organizations thrive in competitive markets.

Quality Control Vs. Quality Assurance

While often used interchangeably, Quality Control (QC) and Quality Assurance (QA) serve different but complementary purposes in quality management. Understanding the difference between QC vs QA helps organizations design stronger processes and deliver better results.

| Aspect | Quality Control (QC) | Quality Assurance (QA) |

| Definition | QC focuses on identifying defects in the final product or service | QA ensures that processes are followed to prevent defects during production |

| Focus | Detecting and fixing defects after the product is produced | Preventing defects by improving processes and ensuring quality standards are met |

| Objective | To verify that the product meets quality standards | To ensure the overall process leads to high-quality results |

| Timing | Happens after the product is created | Happens during the development or production process |

| Approach | Reactive – identifies issues after production | Proactive – works to prevent issues before they occur |

| Methods Used | Testing, inspections, sampling, and measurements | Audits, process checks, training, and standards implementation |

| Responsibility | Typically performed by a specific QC team or department | Involves everyone in the organization as part of their workflow |

| Tools | Inspection reports, testing protocols, checklists | Process standards, process mapping, and continuous improvement tools |

| Examples | Product testing, visual inspections, defect reports | Process optimization, quality standards development, training |

| Goal | To identify and correct defects in products or services | To improve the process to prevent defects and ensure consistency |

Example of Quality Control in Industries

Real-world examples of Quality Control show how QC principles apply across different sectors. Each industry adapts QC methods to meet its unique challenges, but the goal remains the same: delivering consistent, safe, and reliable outcomes.

Manufacturing Example

A toy manufacturer establishes strict QC checks for stitching, material safety, and durability. Inspectors test random batches to ensure every toy meets safety regulations and quality standards before reaching the market.

Food Industry Example

Food companies conduct QC checks for contamination, freshness, and labeling accuracy. Sampling methods, lab testing, and compliance audits safeguard public health while maintaining consumer trust.

Pharmaceutical Example

Drug manufacturers use QC testing to verify potency, purity, and dosage accuracy. Regulatory authorities such as the FDA or EMA require rigorous QC before medicines can be released.

Software Example

In IT, QC is carried out through system testing, bug tracking, and functionality checks. This ensures applications work smoothly, meet performance benchmarks, and provide a consistent user experience.

Service Industry Example

Hospitals and clinics apply QC through patient feedback surveys, process audits, and compliance with healthcare standards. This guarantees safety, service consistency, and trust.

These examples of Quality Control in industries demonstrate that QC isn’t limited to manufacturing; it’s a universal discipline ensuring quality across every sector.

Careers in Quality Control

Quality Control (QC) offers a rewarding career path for example Quality Control Inspector, Quality Control manager, etc. for those who enjoy working with others, presenting results, and striving for improvements and safety. The qualifications and skills needed for a career in QC vary depending on the industry, but here are some general guidelines:

Educational Requirements

- Entry-level QC positions typically require at least a high school diploma

- A bachelor’s degree may be necessary for more advanced roles, depending on the industry

- Industry-specific background knowledge is often important

Licenses and Certifications

- Some businesses and sectors may require specific licenses and certifications

- Professional development courses and certifications, such as Six Sigma or a Certified Quality Inspector designation, can be beneficial

Skills Needed

- Attention to detail is crucial in QC roles

- Mathematical and mechanical skills are often required

- Physical strength can be important, especially in manufacturing environments

- Technical knowledge relevant to the specific industry is essential

- The ability to perform well under pressure

QC jobs are not just about spotting defects; they are about safeguarding customer trust and driving operational excellence.

Career Path

- The career trajectory in QC can vary by industry, but it generally involves gaining years of professional experience in your field

- Initially, you might start as a quality assurance or control associate

- With experience, you could advance to a senior specialist role and lead teams of QC specialists

A career in Quality Control is dynamic and requires a blend of education, specific skills, and continuous learning. It offers opportunities for growth and specialization, particularly for those passionate about ensuring the quality and safety of products and services.

Conclusion

Quality Control is not just a technical process; it is the foundation of trust, consistency, and customer loyalty. By enforcing clear quality standards, businesses safeguard their reputation, reduce risks, and improve efficiency in a competitive marketplace.

Understanding the definition of Quality Control and its true meaning helps organizations see it not as an optional function but as a strategic advantage. From manufacturing and pharmaceuticals to services and technology, QC ensures reliability, compliance, and long-term success.

Today, the importance of Quality Control cannot be overstated. It empowers companies to deliver products and services that meet expectations, comply with regulations, and earn customer confidence.

If you’re looking to strengthen your expertise, consider exploring Quality Management training programs to apply these principles effectively in your career or business.

FAQs on Quality Control

Who is responsible for Quality Control in a company?

A dedicated QC department typically manages Quality Control, but it also involves employees across various levels of the organization. Depending on the industry and company size, QC responsibilities can include technicians, engineers, managers, and even frontline workers.

How does Quality Control differ in manufacturing and services?

QC often focuses on physical product inspections and testing against defined specifications in manufacturing. QC might evaluate the delivery process, customer satisfaction, and service consistency.

Can Quality Control impact a company’s financial performance?

Yes, effective QC can significantly impact a company’s financial performance. It can reduce costs associated with defects, improve customer satisfaction and loyalty, and enhance brand reputation, leading to better sales and profitability.

How do technology and automation influence Quality Control?

Technology and automation have revolutionized QC by introducing more accurate and efficient methods for testing and monitoring. This includes using AI, machine learning, and automated inspection systems, which can detect defects more reliably and quickly than manual methods.

What role does customer feedback play in Quality Control?

Customer feedback is crucial in QC, providing real-world insights into product performance and customer satisfaction. This feedback can be used to make continuous improvements in product quality.

Are there any global standards for Quality Control?

Several global standards for QC, like ISO 9001, provide frameworks for quality management systems and are widely recognized across industries.

How often should Quality Control processes be reviewed and updated?

QC processes should be reviewed and updated regularly to adapt to new technologies, changes in consumer expectations, and evolving industry standards. This ensures that the QC processes remain effective and relevant.

What is the impact of Quality Control on product development?

QC significantly impacts product development by ensuring that new products meet quality standards before they reach the market. This can prevent costly recalls and enhance customer trust in new products.